For over fifty years, silicon has been the dominant material in the semiconductor industry, enabling the digital revolution and changing the face of humanity. Silicon technology brought the world from early computers to smartphones, autonomous vehicles, and computer-embedded electronic devices in every aspect of our lives. However, in recent years there has been growing recognition that silicon is reaching its physical limits, and the industry must turn to innovative materials to continue on the path of technological advancement.

The limitations of silicon are particularly felt in areas requiring high energy efficiency, high voltages, high frequencies, and extreme temperatures. The enormous growth in energy consumption of data centers, electric vehicles, and advanced communication networks requires solutions that allow for more efficient energy conversion and advanced heat management. This is where new materials such as gallium nitride (GaN) and silicon carbide (SiC) enter the picture, leading the next wave of innovation in the semiconductor field.

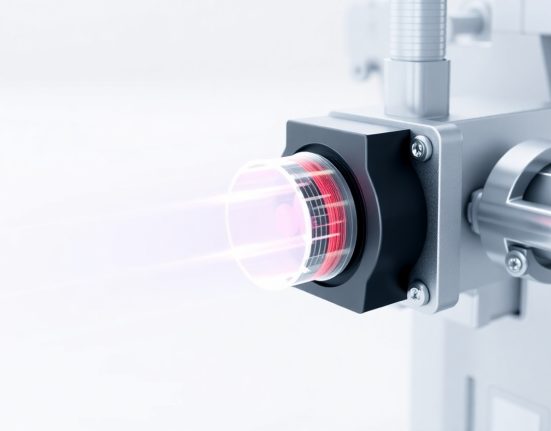

Gallium nitride (GaN) is one of the most promising materials in the industry. Its unique properties include a wide energy gap, high electron mobility, and excellent thermal conductivity. These properties allow GaN-based chips to operate at higher voltages, higher frequencies, and higher temperatures than traditional silicon chips. The most significant advantage of GaN is its high energy efficiency. GaN-based electrical circuits can achieve energy conversion efficiency of over 95%, compared to about 85% in standard silicon technologies, a reduction that translates into significant savings in energy and heat emission.

Commercial applications of GaN technology are already on the market, primarily in the field of power supplies and chargers for mobile devices. GaN chargers enable faster charging while maintaining smaller dimensions and lower heat. Companies such as Navitas Semiconductor, GaN Systems, and Efficient Power Conversion (EPC) are leading research and development in this field. Another area where GaN is beginning to integrate is high-frequency wireless communication, especially in 5G and 6G infrastructures, where it enables faster and more energy-efficient data transmission.

Meanwhile, silicon carbide (SiC) is another material gaining momentum in the industry. SiC offers particularly good resistance to high voltage and high temperature conditions, making it ideal for applications in electric vehicles and industrial systems. The main advantage of SiC is its ability to carry stronger currents than regular silicon, allowing for smaller and more efficient electrical circuits. Tesla was one of the first to adopt SiC technology in the inverters of its electric cars, contributing to improved driving range and vehicle performance.

Companies such as Wolfspeed (formerly Cree), STMicroelectronics, and Infineon are among the leaders in developing SiC technology, with investments of billions of dollars in new manufacturing facilities in recent years. According to market forecasts, the SiC-based components market is expected to grow at an average annual rate of over 30% in the next five years, driven mainly by the growing demand for electric vehicles and renewable energy infrastructure.

Additional advanced materials in research and development include gallium oxide (Ga2O3), which offers an even larger energy gap than GaN and SiC, and synthetic diamond, considered the “dream material” of the semiconductor industry due to its excellent properties in heat conduction and electrical resistance. However, these materials still face significant challenges in mass production and industry integration.

The challenges in adopting new materials are substantial. Production costs of GaN and SiC-based chips are still significantly higher compared to silicon, mainly due to less accumulated experience in mass production processes. Additionally, there are technical challenges in integrating new materials with existing technologies and adapting existing production processes to these materials. However, as technology advances and production volumes increase, costs are expected to decrease significantly in the coming years.

The environmental impact of the transition to new materials is significant. The improved energy efficiency of GaN and SiC-based semiconductors leads to energy savings in a wide range of applications, reducing the industry’s carbon footprint. In electric vehicles, for example, the use of SiC components can lead to an improvement of up to 10% in driving range, reducing the required battery size and the use of expensive resources such as lithium and cobalt.

The transition to new materials also involves geopolitical challenges. The raw materials required for GaN and SiC production are not as common as silicon, and some are concentrated in specific countries. For instance, China controls a significant portion of the global gallium market, creating potential risks in the supply chain. Countries and large corporations are now investing in research and development of alternative supply sources and more efficient recycling processes to reduce dependence on limited sources.

Despite the challenges, the future of the semiconductor industry clearly points towards increased adoption of innovative materials. The massive investments by giant corporations and governments worldwide in GaN, SiC, and other advanced materials technologies testify to the recognition that this is the only way to continue the path of innovation and performance improvement. For end consumers, the transition to these materials will be reflected in smarter, more energy-efficient devices with better performance and less heating. In the coming years, significant development is expected in the field, with increasing penetration of GaN and SiC technologies into a wide range of applications in the electronics, automotive, communications, and energy industries. The semiconductor industry, which has been based for decades on one dominant material – silicon, is becoming more diverse, with a variety of materials tailored to specific applications. This trend will not only enable further technological advancement but also significantly contribute to global efforts to reduce carbon emissions and address climate change.