In an era of advanced automation and complex industrial processes, control rooms have become the beating heart of many industries—from energy production to food manufacturing, from smart transportation to the chemical sector. And they’re far more than just rooms filled with screens—they’re the nerve centers where data flows in, critical decisions are made, and the stability of massive systems is quietly maintained. As someone who’s genuinely fascinated by industrial technology and visits these kinds of facilities now and then, I’m constantly amazed by the blend of engineering precision, smart design, and human decision-making working together in real time.

Designing a control room is all about balance. On one hand, you need maximum safety, ergonomic layouts, and the ability to respond instantly in an emergency. On the other, you want a calm, comfortable space where operators can focus for long hours, sometimes monitoring hundreds of parameters at once. The location of the control room is a big decision—should it be right in the center of the plant, or completely isolated? Should there be one main command center or multiple sub-control rooms? Each choice affects response times, accessibility, and how much independence each operational unit has.

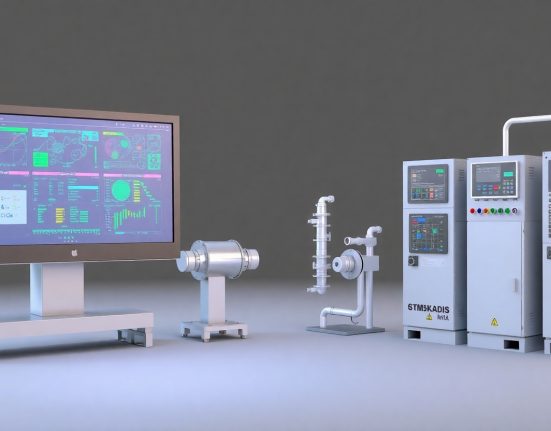

The equipment you’ll find in control rooms varies depending on the industry, but there are a few things that are pretty much universal: big video walls, advanced SCADA systems, custom-designed operator desks, large touchscreens, communication systems, even biometric security for staff access. Every piece of gear is chosen for reliability, redundancy, and quick usability. Some of the newer setups even include AI-based systems that help predict failures before they happen and assist in managing complex scenarios. It’s one of those fields where the innovation just doesn’t stop.

Operating a control room takes more than technical skills—it takes systems thinking. The operator isn’t just “watching”; they’re responsible for the health of an entire operation. They have to prioritize alerts, understand real-time data, and follow clear protocols while also applying good judgment. The biggest challenge? When things go wrong. That’s when the calm turns into high-stakes decision-making, and every second matters. Working in this environment demands strong nerves, sharp analysis, and the ability to function smoothly as part of a team—especially when multiple issues arise at once.

There’s something magical about control rooms. The quiet hum, the blinking lights, the endless data feeds—it’s all part of a larger story of steady hands making sure massive systems keep running. What draws me to this field is that it’s where engineering, humanity, and technology meet in the purest way—not to show off, but to ensure that everything just keeps working, day after day.