In the world of industrial automation, two main types of control systems stand out as the go-to solutions for managing complex processes – SCADA and DCS. While they share similar goals, there are important differences between them that can really affect which system is best for a given project or operation. As someone who’s passionate about automation and control systems, I find this topic especially interesting because it blends technology with real-world industrial challenges. Understanding these differences helps get the most out of efficiency and reliability in factories and facilities.

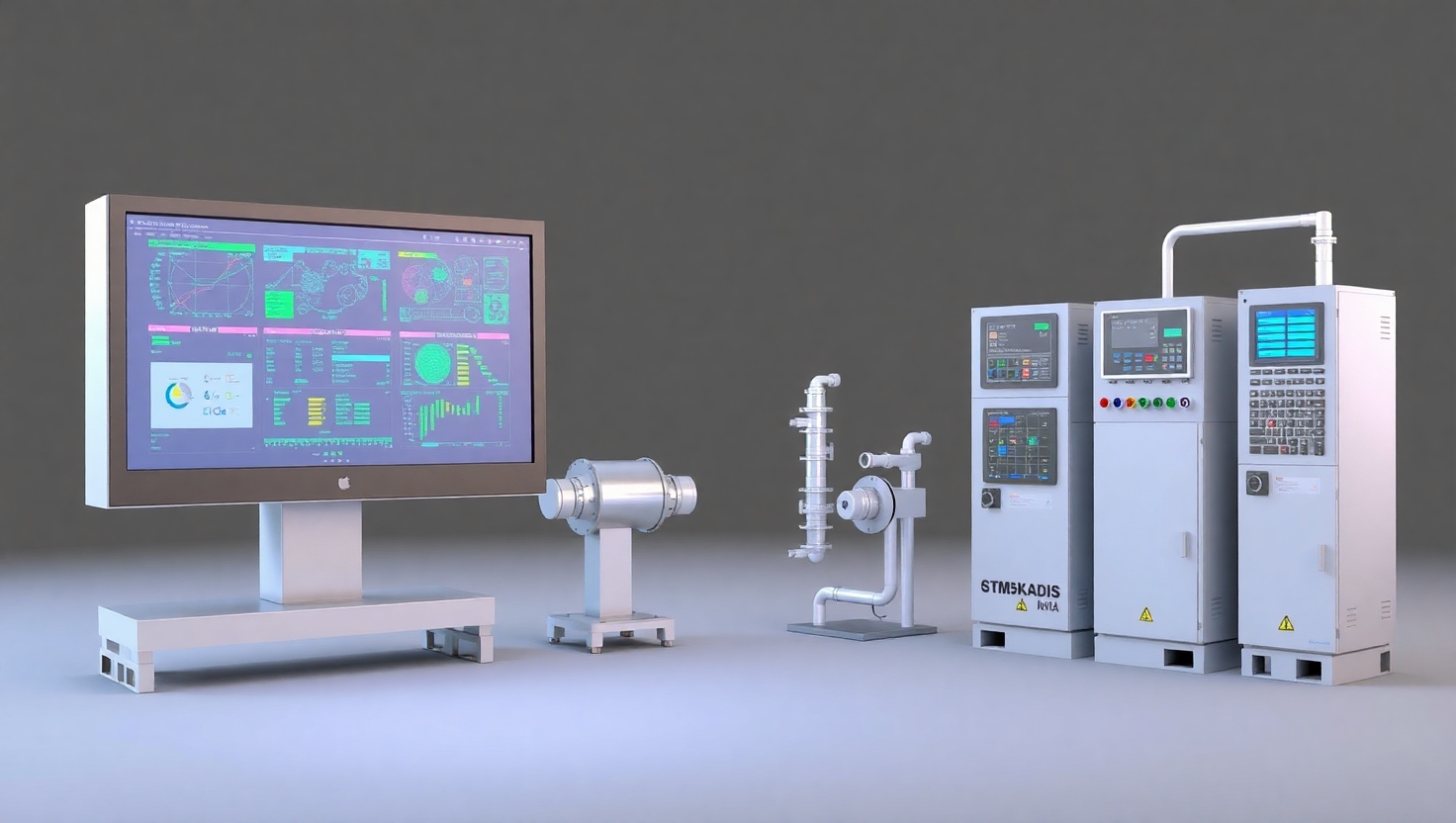

SCADA (Supervisory Control and Data Acquisition) was originally designed to gather data from remote locations, especially in widely spread facilities like power grids, pipelines, water treatment plants, and more. The system focuses on centralized monitoring and control, allowing operators to keep an eye on hundreds or even thousands of remote data points in real time. What makes SCADA unique is its flexibility and ability to handle very large physical setups, where each station mostly runs independently and sends data back to a central control center. It’s especially suited for environments with unstable or intermittent communications and for managing projects that are spread out geographically.

On the other hand, DCS (Distributed Control System) is aimed at controlling and managing continuous and complex processes, mainly in plants where operations run non-stop, such as chemical production, food processing, oil refining, energy generation, and more. In a DCS, control is distributed across local controllers placed close to the process itself, allowing for quick and precise responses. The system is built to provide high reliability, stability, and accurate control of process parameters, making it perfect for managing complicated processes with high levels of automation. DCS focuses on deep process management, with interfaces and data handling designed to ensure smooth operation and prevent failures.

When it comes to deciding which system fits which use, it’s important to understand the unique characteristics of the facility or system you want to manage. If you’re dealing with a facility that has a large, distributed physical infrastructure, like water networks, energy grids, or transportation systems, SCADA is usually the preferred choice. It offers an efficient, modular solution for remote monitoring and control, with an emphasis on data collection and visualization in real time from all over the system.

On the other hand, for plants with continuous processes that require precise control and fast data processing, DCS is the smarter choice. It enables real-time response and maintains quality and stability throughout the production chain, and it’s especially suitable for environments where even a second of process disruption can cause significant damage or losses.

At the end of the day, the real world doesn’t always force a strict choice between SCADA and DCS. Sometimes, the systems complement each other and are integrated to create a comprehensive control setup that provides both remote oversight and detailed process management. All tailored perfectly to the specific needs of the organization and the processes it runs.

I love this field because it shows how technology can turn complicated and widespread processes into something easier to manage, while maintaining reliability, efficiency, and safety. Choosing the right system between SCADA and DCS isn’t just a technical decision – it’s a strategy that directly impacts how factories and industrial facilities operate every day.