PLCs are the beating heart of automation systems in industry, allowing precise, reliable, and fast control over complex processes. Working with them might seem a bit intimidating at first, especially if you’re new to the world of control and automation, but over time it becomes an exciting and creative journey full of learning opportunities. PLC stands for Programmable Logic Controller, which means a programmable logic controller that replaces traditional control panels with relays and offers flexible programming and easy updates.

When starting to work with a PLC, it’s important to first understand the goal of the system you’re building and the process you want to control and monitor. Every project begins with a clear understanding of the requirements, like what sensors are involved, which actuators need to operate and when, and what situations or scenarios might occur. After that comes the stage of choosing the right type of controller. There are different kinds of PLCs, ranging from simple units designed for smaller tasks to advanced systems that can support thousands of inputs and outputs and very complex processes.

Learning to program a PLC is usually done using standard languages, the most popular being Ladder Logic, which visually resembles relay logic and makes it very approachable for beginners. There are also other languages like Function Block Diagram or Structured Text that offer alternative ways to program the controller. It’s important to practice and not be afraid of making mistakes early on because working with PLCs improves your understanding of processes and your ability to troubleshoot quickly.

Another key part is using simulators and dedicated programming software that let you build your program and run it in a virtual environment before connecting the controller to the real system. This helps reduce errors, saves time, and boosts efficiency. As you gain experience, you can dive deeper into topics like communication between PLCs, integration with SCADA or MES systems, and even developing advanced control systems using IoT.

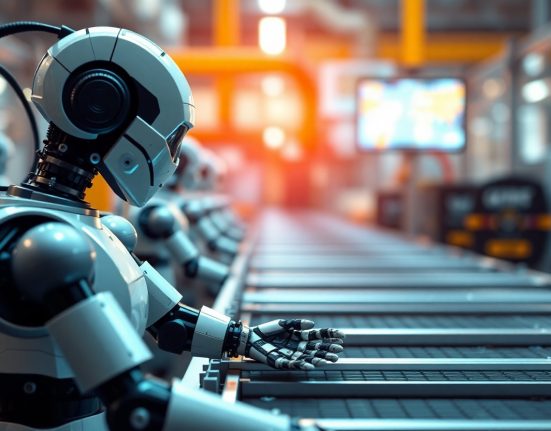

What’s amazing about working with PLCs is the ability to take a complex physical system and control it automatically and accurately, improving processes, enhancing safety, and lowering operational costs. This field is constantly evolving, with new technologies continuously expanding the capabilities and functions of controllers. Those who dive into this world become not just technicians but creators and developers who can turn ideas into real industrial solutions.