Proximity sensors are truly one of the most fascinating and essential tools in today’s world of industrial control. In an age where automation is taking center stage in factories, these sensors allow systems to detect the presence or absence of objects without any physical contact. The idea is simple but brilliant – instead of relying on touch or mechanical switches, proximity sensors use advanced technologies like infrared, electromagnetic waves, or ultrasonic signals to capture real-time information and boost the efficiency of industrial operations.

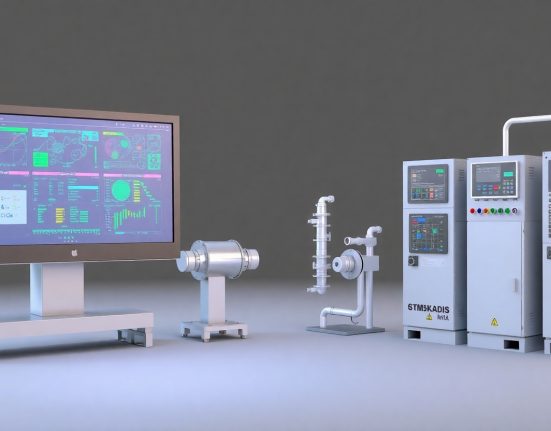

What excites me most about this field is the perfect blend of simplicity and purpose. In many factories, proximity sensors help identify the exact position of parts during the manufacturing process or ensure machines only operate when all components are in place. They prevent costly mistakes, reduce safety risks, and allow continuous operation without constant human intervention. When you think about it, these sensors make the factory smarter and more aware of its surroundings – something that was hard to imagine just a few decades ago.

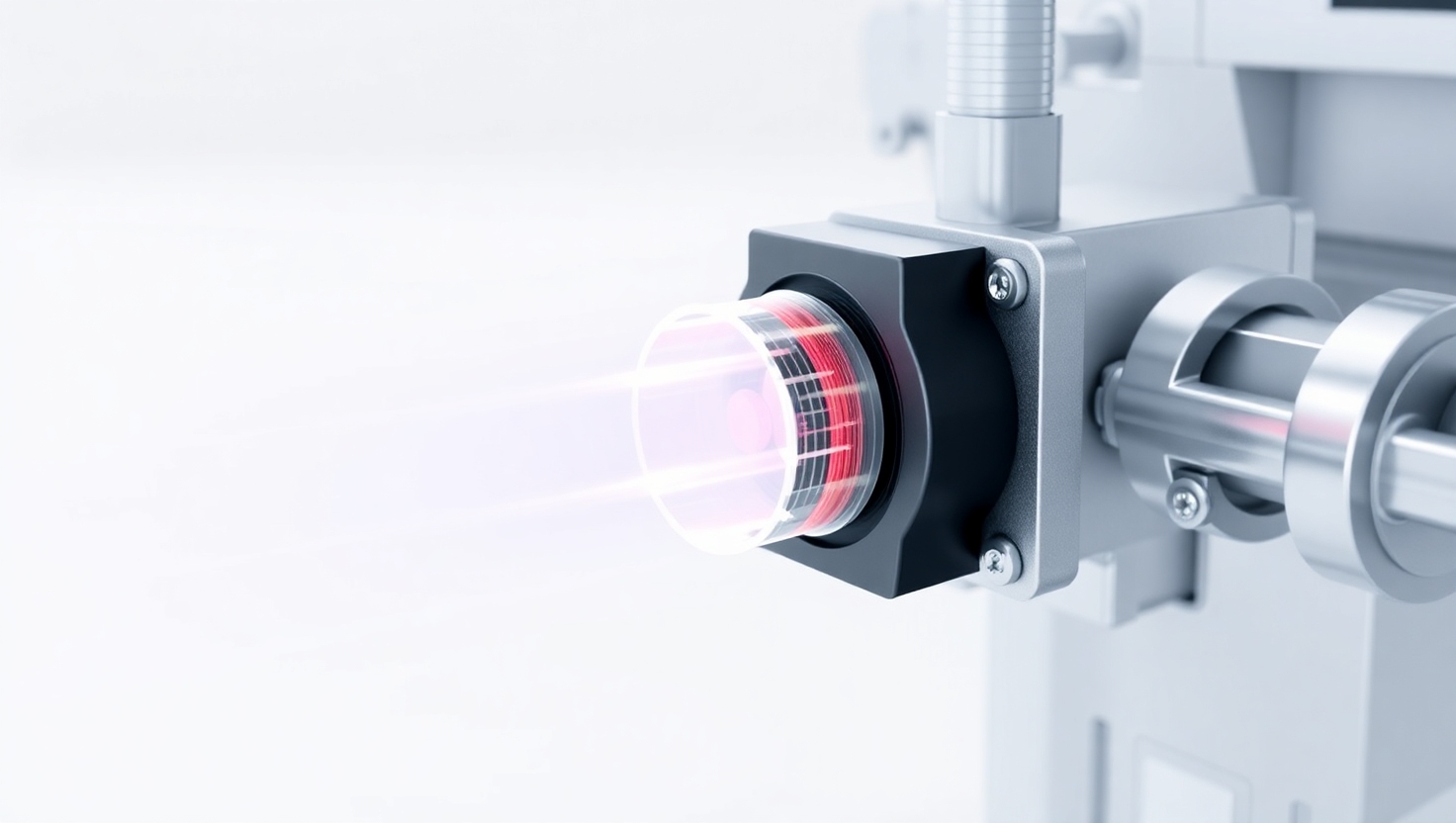

What really makes proximity sensors stand out is their ability to work in tough conditions – whether it’s dust, oil, moisture, or extreme temperatures. Unlike contact-based systems that are more prone to wear and failure, proximity sensors maintain stability over time and deliver high reliability. That’s why they have become an integral part of modern control systems, from managing robots to smart maintenance setups that spot issues before they even happen.

Beyond the technical side, I’m always impressed by the creative possibilities this technology opens up for engineers and developers. There’s a real sense of harmony between hardware and software that lets people build custom solutions for almost any challenge. Proximity sensors aren’t just about detecting position – they can also measure distances, count items at high speed, or even sense movements and actions of people in the workspace – all aimed at making factories more efficient, safer, and smarter.

Finally, looking at the Fourth Industrial Revolution, proximity sensors are a perfect example of technology bringing the future into the present. They are part of bigger systems that enable real-time data collection, smart analysis, and immediate decision-making, helping streamline processes, save resources, and cut down on human errors. Working with these sensors isn’t just technical – it’s an experience of creating something alive within the industrial system, turning simple machines into intelligent and responsive tools.